NEW Glue Pulling Systems- In Stock!

NEW Glue Pulling Systems- In Stock!

BODYSHOP

WORKSHOP

WELDING

TOOLS

SAFETY

WHY DO I BLOW HOLES WHEN SPOT WELDING ON CARS

November 30, 2020 5 min read 1 Comment

RESISTANCE WELDING

Your spot welder isn't officially called a spot welder, its a resistance welder. It uses the resistance in a weld joint to generate heat. This heat builds up at the highest resistance (between the plates to be welded) until it is molten. This molten metal is then squeezed together between the electrodes and allowed to go cold, forming a spot.

THE STACK

In the welding stack, you have three resistances

- The first layer of material to be welded (steel)

- An air gap - even when the steels are clamped together, in theory, an air gap to electricity.

- The last layer of material to be welded.

The stack above consists of three resistances, the two sheets of steel and the air gap.

Even with the pressure of the electrodes clamping the two sheets of steel together, there is still an air gap.

These accumulating resistances will generate heat as the welding current is passed through them, but the crucial point here is the centre, the air gap.

Air is VERY HIGH RESISTANCE, and as such, the centre point in the welding stack is the place with the most; therefore, it generates the most heat. This heat will continually build up as the current passes through it until, eventually, it becomes molten and liquid.

The squeezing pressure from the electrodes then squeezes this liquid together forming a ball or spot.

In a weld stack if the air gap is high, then the heat produced at this point will be very high. If there isn't enough pressure to control this heat, then expulsion will occur (sparks and splash outs).

If the gap is too large, then a hole may occur.

MANY THINGS CAN PRODUCE AIR GAPS.

1, If your electrode doesn't fit into the indentation of an old spot weld then this will create a large air gap under your weld electrode, panel explosion is inevitable as too much heat will be generated where the electrode meets the steel.

All of these faults will cause explosions and because the panel you are welding on is generally the thinnest, this is the one that blows, so creating a hole.

EXPLOSIONS DUE TO BAD ELECTRODE SHAPE OR CONDITION.

The electrode is the primary electrical contact for the current to flow; a good electrical connection is critical so that the only heat produced is in the centre of the welding stack.

A poorly conditioned or unclean welding electrode creates surface resistance between the electrode and the surface of the steel. This, in turn, will create extra unwanted heat at the electrode contact point. Usually, the operator will see "sparks" or "splash" as an indication of this excess heat, but if the heat generated is too excessive, it could ultimately blow a hole.

GLUES AND PAINTS IN BETWEEN YOUR STEEL PANELS.

The glue or zinc protection spray your place on the new body panel before fitting are not electrically conductive, they are what we call, "insulators", in that they won't allow electrical current to flow through them. This wouldn't be a problem in a typical weld joint as there is no alternative route for the current to flow so you just wouldn't get a weld, but in a car, there are lots of alternative current paths. These paths we call shunts.

Electrical current can travel great distances if it's able too, therefore when you weld if there is an insulator like glue in between the steels then the electricity cant flow here. Therefore it looks for the best (least resistive) route to flow and return to the welder via the other electrode at the back of the panel. The greater the distance this current has to travel through the steel to return (through the rear electrode), the more heat is generated at the electrodes contact point.

If you do not have enough electrode tip pressure to control this extra heat, then a hole in your panel may be observed. This effect is called Shunting!

We can use Shunting when spot welding to generate extra heat and therefore burn away the glues, but it has to be controlled and within 2-3 inches of the intended new weld.

A shunt can be, mole/vice grips, a previous spot weld, a bolt or screw etc.

During repair it's crucial for you to understand Shunting as it can be the most significant source for blowing holes in your panel, Shunting can help you, and it can also hinder you in making a good weld.

So let's look at Shunting and how it works when spot welding.

As you can see, the welding current would rather travel through the steel via an older spot weld (shunt) than jump the higher resistance gap you are trying to weld.

This is bad, although on the outside the indentation and weld appearance may look like you have produced a good weld, in the middle (the critical part) your weld nugget size will be reduced due to the loss of weld current.

Manufacturers understand this and alter the weld gap between spot welds to compensate for this Shunting.

The distance between the spot welds will vary according to the resistance qualities of the steel being welded. The lower the steels electrical resistance, the larger the gap and vice versa. This brings us to the importance of weld nugget size (we will cover this in another blog post at a later date).

You need to understand the process of Shunting so that you may reduce the chances of blowing holes in your new body panel.

CONCLUSION

So in conclusion, blowing holes in your panel when spot welding may not the fault of the spot welding machine, its probably the fault of :

- Your joint preparation,

- Your electrode placement

- shunting

- Lack of pressure at the electrodes

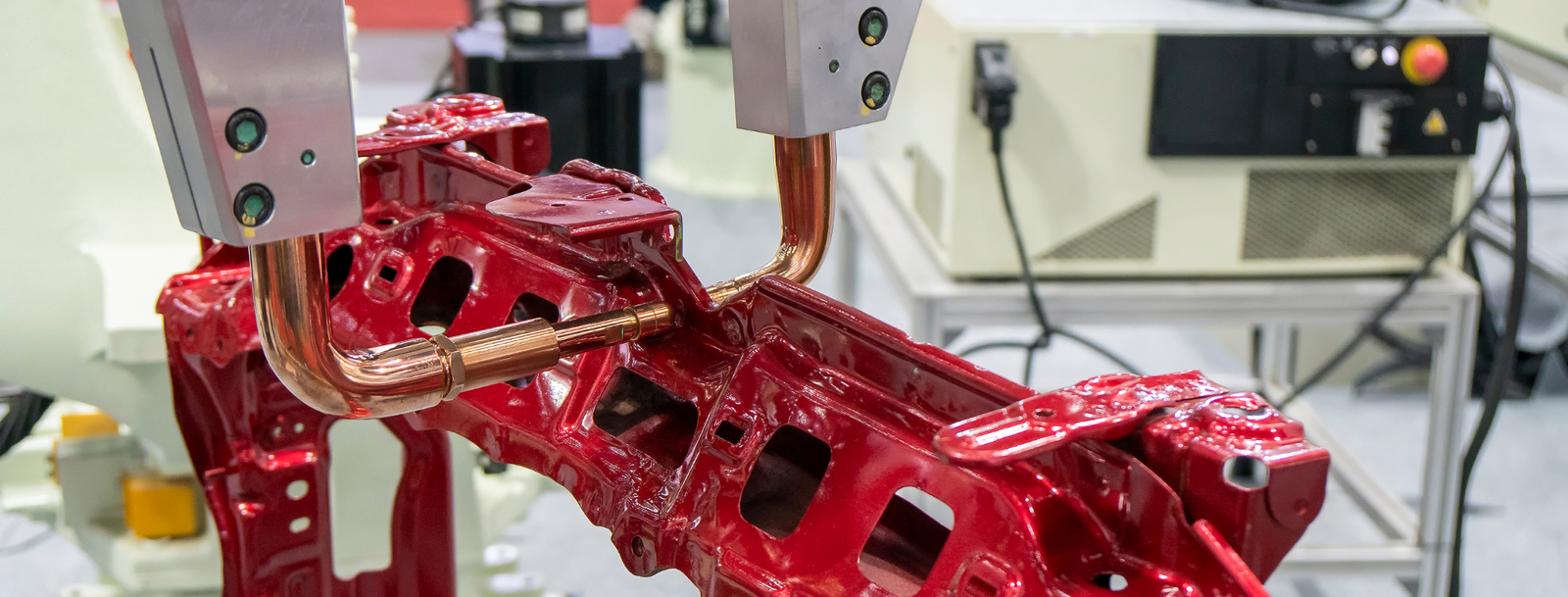

Header Picture with thanks from ARO Technology

Last Illustration picture with thanks to Renault Training.

1 Response

Leave a comment

Comments will be approved before showing up.

Mustafa Abdulaziz

October 30, 2023

Dear sir good day.

I ’d like you to help in welding a copper tube to a flat copper sheet if it possible please contact me on mail for importance