NEW Glue Pulling Systems- In Stock!

NEW Glue Pulling Systems- In Stock!

BODYSHOP

WORKSHOP

WELDING

TOOLS

SAFETY

What is IMI Training?

IMI Training refers to the courses and certifications offered by the Institute of the Motor Industry (IMI), a professional association that sets the standards for automotive professionals in the UK. The IMI provides a range of qualifications designed to enhance the skills and knowledge of individuals working in the motor industry. These qualifications are recognized globally and are highly valued by employers, making them a vital component of career development in this field.

As an IMI Approved test center we are able to carry out this testing on your premesis so that your technicians get the best training in the comfort of their own surroundings.

Where is the Training carried out?

As an IMI Approved test center we are able to carry out this testing on your premesis so that your technicians get the best training in the comfort of their own surroundings.

Why Choose IMI Training?

Choosing IMI Training is a strategic move for anyone looking to establish or advance their career in the automotive industry. Here are some compelling reasons to consider:

- Industry Recognition: IMI qualifications are widely recognized and respected by employers, ensuring that your skills are validated by a reputable authority.

- Career Advancement: With IMI certifications, you can enhance your employability and open doors to new career opportunities, whether you're just starting or looking to climb the ladder.

- Skill Development: IMI Training focuses on practical skills that are directly applicable to the workplace, ensuring that you are well-prepared for real-world challenges.

AOM-009 WELDING COMPETENCE AND COMPLIANCE

BS 4872 Part 1 MIG/MAG Testing Details

This is a non-procedural welding test to prove competence on steel. The test involves four welds in the vertical and horizontal upside-down positions. Two welds are fillet, and two are butts.

The thickness of the sample materials is 1.0mm, although some manufacturers also request 2mm and 3mm (Porsche).

Welds are tested onsite for:

- Visual

- Nick Break

- Macro

Advice and training are offered to each candidate to enable the best opportunity to pass at this level.

BS 1140 Spot Welding Testing Details

Technicians are asked to perform two spot welds on two sheets of 1mm steel. Nugget diameters are required to be of the sizes 5mm and 8mm.

Testing of the welds is by tear testing.

TESTING PRE-REQUISITES

Attending technicians must be able to weld unsupervised on vehicle body panels and ideally have experience in MIG/MAG welding. Technicians must have good eyesight, and if they wear spectacles, they must have them available when the test is conducted.

TECHNICIANS KEY BENEFITS

- An IMI accredited certificate

- Inclusion on the IMI professional register

- Industry-wide recognition of their skills and abilities

- Advice and guidance for development

- An opportunity for career progression

EMPLOYERS BENEFITS:

- Assurance as an owner and to your customers that your technicians are up to the National Welding Standards as dictated by The Welding Institute.

- Proof of current welding competence for liability insurance and quality control.

- A benchmark for technician recruitment and training.

COURSE CERTIFICATION

IMI Certificated - IMI Certification fee of £45 is applicable for registration and supplied certificate

book this course - 0161 223 1843

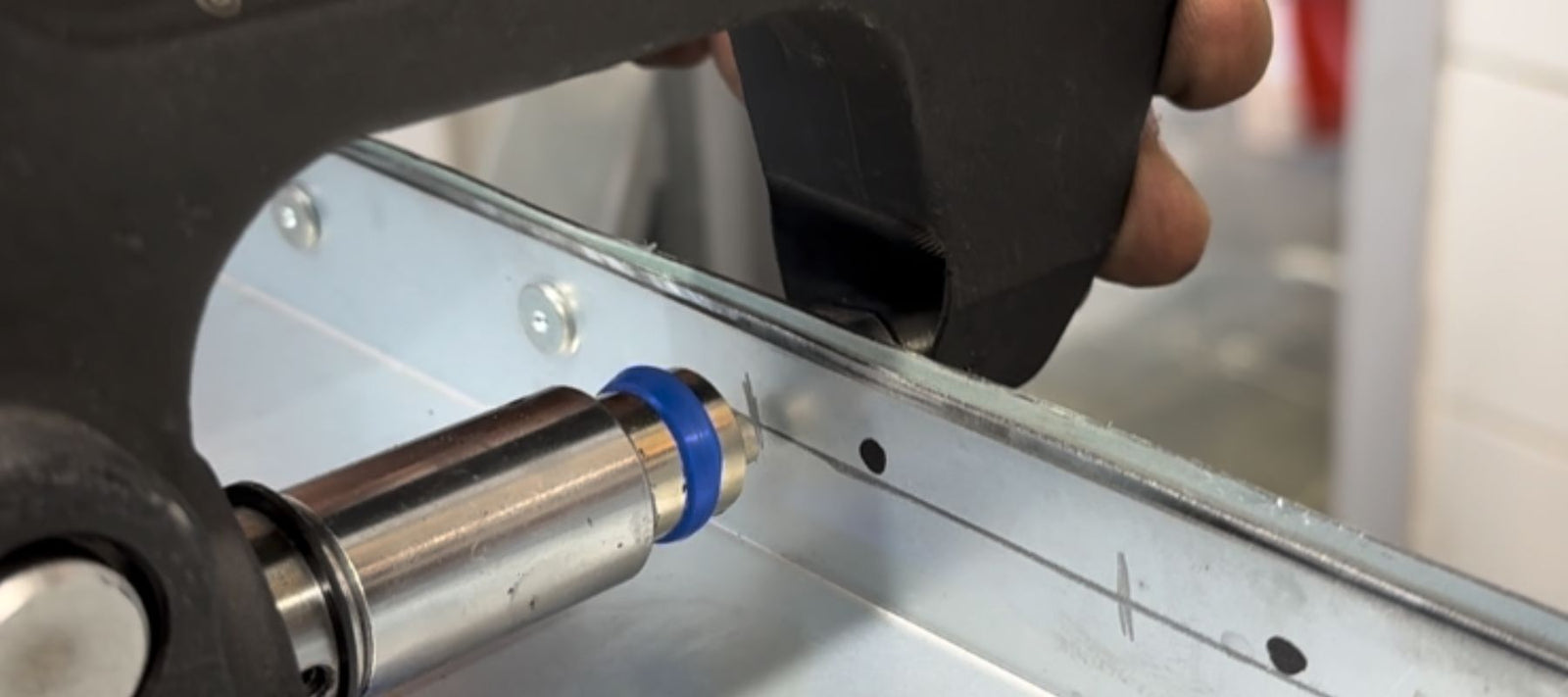

AOM-133: Bonding and Mechanical Fastenings.

What is The AOM-133 test?

The AOM-133, is a unique module designed specifically for technicians whose job role involves the repair of vehicle bodies. This module focuses on the replacement of a panel section that is secured by adhesive/bonding and mechanical fastenings. It has been developed to help technicians demonstrate their capability in following researched repair methods, carrying out modern joining techniques, and meeting the criteria outlined in BS10125.

Employers KEY BENEFITS

- An IMI accredited certificate

- Inclusion on the IMI professional register

- Industry-wide recognition of their skills and abilities

- Advice and guidance for development

- An opportunity for career progression

Attending technicians must be able to replace a sill section sample unsupervised as per a written method statement. They should ideally have experience of this type of work or attended a pre-course. on vehicle body panels and ideally have experience in bonding and riveting. Technicians are required to have with them their safety equipment and basic hand tools such as a hammer, chisel, dril, vice grips, dollies and measure. They can use their own SPR rivet tool or one can be supplied. Time allocated is 4.5 Hours to completion.

Book The Course- 0161 223 1843