NEW Glue Pulling Systems- In Stock!

NEW Glue Pulling Systems- In Stock!

BODYSHOP

WORKSHOP

WELDING

TOOLS

SAFETY

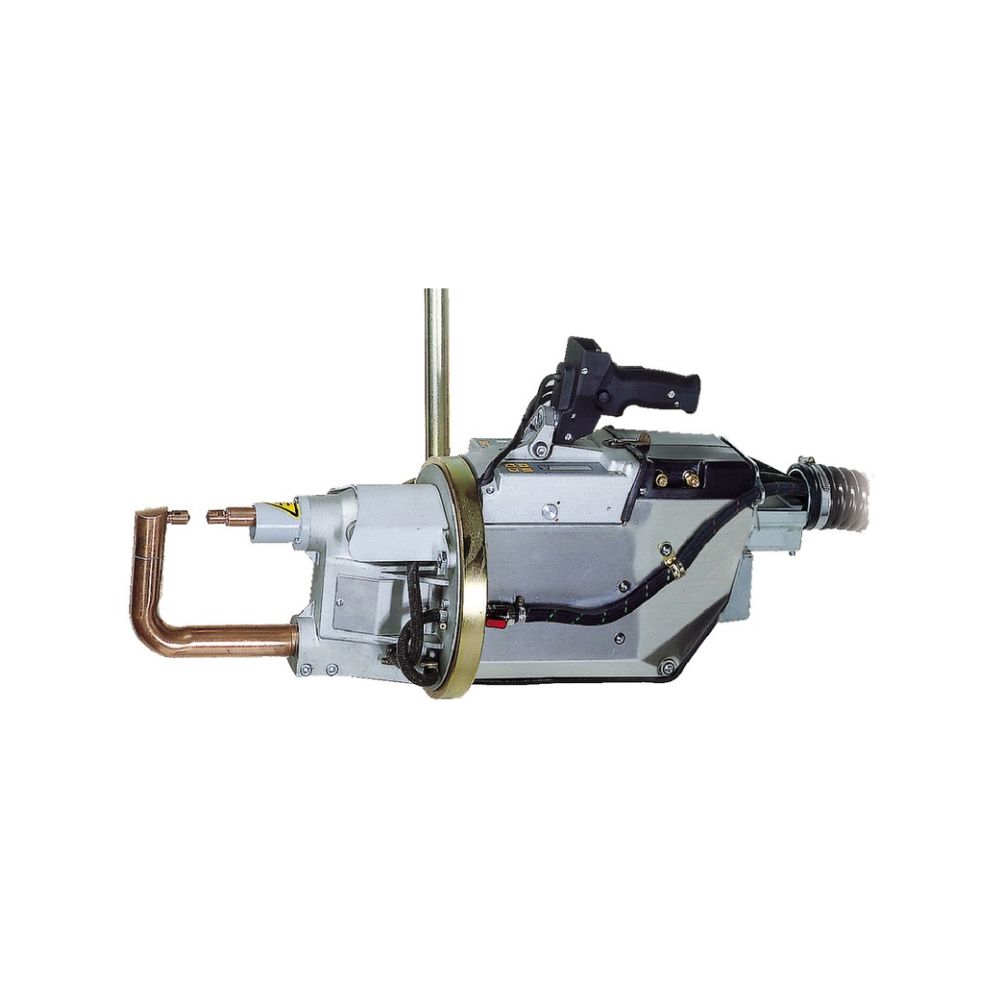

TECNA C TYPE SUSPENDED SPOT WELDER

3323/TE470

Brand: Tecna

Tecna Industrial Suspended Spot Guns With Microprocessor Control Unit TE470

The TECNA 3323/TE470 suspended spot welder features C-type arms that are water-cooled and ideal for joining sheet metal edges in a production setting. A balancer can be used with this welder to easily manoeuvre around the work for optimal efficiency. With a 23kVA power output, this welder is capable of welding mild steel panels that are 4+4mm in thickness.

The benefits of the "c" gun are that better pressure is maintained at the electrode tips compared to a Tecna X-type spot welder giving better welds without splash-out.

Suitable for welding galvanised steel

16 kVA foot-suspended X Type arm spot welder designed to meet various spot welding needs. TECNA rocker arm spot welders are most commonly used as mobile spot welders for production applications.

TECNA features different arm lengths, allowing for better work flexibility.

Pneumatic operated suspended gun, with integrated TE330, TE450, TE470 or TE480 microprocessor welding control unit

WHY BUY FROM BWS?

- Technical Support ✓

- Service Engineers ✓

- Business Account ✓

- Professionally Installed onsite by Qualified welding engineers ✓

DOWNLOAD

![]()

TECNA TE470 CONTROL UNIT

The TE470 is a welding control unit specifically designed for suspended resistance welding guns. It expertly controls the welder parts, especially the thyristors that regulate the welding current. This control unit has unique features for suspended welding guns, including double stroke control and safety device management on the handle.

While the handle is not a standard component, it can be customized for different working performances. With a capacity to store up to 63 welding programs and the ability to directly recall 2 programs using an external selector, the TE470 provides versatility and efficiency. Each program has 19 adjustable parameters that describe the working cycle, including options for pre-weld current, post-weld current, slope, and pulses. The TECNA TE470 also operates in constant current mode, displaying and regulating the current according to the set limit.

- TE101 weld controls, mounted on the front of the machine, allow the operator to view data while welding.

- Water-cooled transformer, arms and electrodes. Epoxy resin coated transformer for maximum protection.

- Adjustable electrode stroke enables access to a greater range of parts.

- Chromium-copper electrode holders are designed for long life and heavy-duty service. May be mounted at 12° and 90° positions in the arm.

- Adjustable throat depth enables maximum flexibility.

- Ergonomic frame for long term operation in production environments.

- Single foot pedal

Power @50% : 16Kva

Max Power: 35Kva

Max Short Cct Current: 12500

Arm Length: 914mm

Electrode Force: 240 Dan

Supply: 220/400V