WHY BUY FROM BWS?

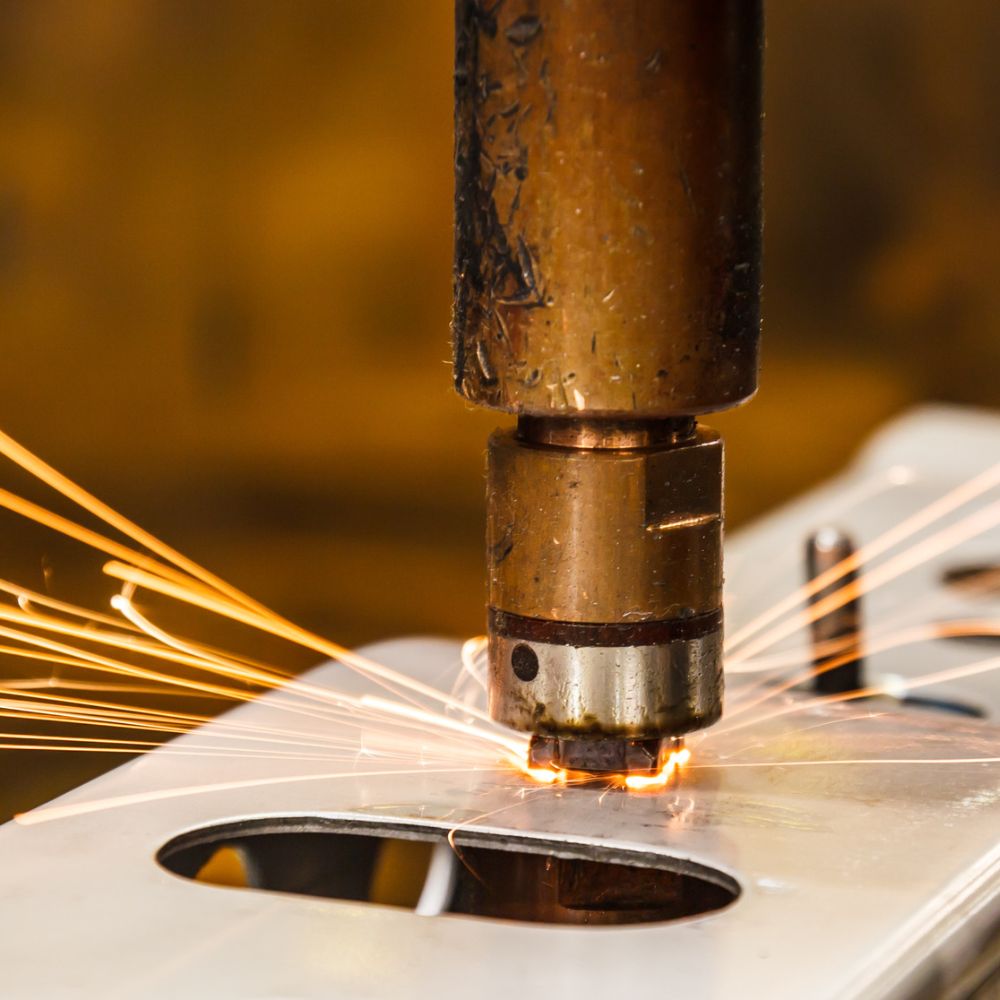

TECNA SPOT WELDING SPECIALISTS

BWS are spot welding specialists, in fact we sold and installed our first TECNA spot welders over 25 years ago to a company making card and seed wire stands. TECNA column welders are ideally suited to wire work. Our engineers are familiar with how these machines work and the applications they work under.

TECNA SUPPORT

We are also able to offer support and servicing nationwide due to our team of mobile service engineers. IF You are looking for a solution to a specific application then please contact us with you specifications and out team will be only too glad to help.

FAQ

-

Stainless steel requires more pressure than than normal ferrous steel to control the heat generated. A 2kVA spot welder will weld it successfully if it can obtain the correct tip pressure. For production a linear projection welder 35kVA would be preferred.

-

The answer is, yes, but it requires greater power and correct pressure to weld successfully due to its inherent quality to conduct heat and electricity easily. This makes it difficult to concentrate the heat between the electrodes in order for them to melt. Very high power and short weld cycles are therefore required compared to steel

-

Tecna SpA Spot Welders are made in Italy at their state of the art factory in in Castel San Pietro Terme (BO) Italy. They have been manufacturing since 1972.

-

Yes they are well designed spot welders produced for the manufacturing industry to give long life and easy serviceability. Tecna are members of many world trade organisations and TECNA S.p.A is certified ISO 9001:2015 e ISO 14001:2015.

-

Yes you can but you will need to pulse weld it. The galvanising coating creates many problems when spot welding, to weld the underlying material successfully you first need to melt away the coating so that the weld current can melt the materials to be joined. This is where pulse is preferred. The first pulse liquifies the galvanised layer whilst the subsequent pulse welds the material. Domed electrodes are also preferred to reduce galv pick up on the electrodes.

SPOT WELDNG