NEW Glue Pulling Systems- In Stock!

NEW Glue Pulling Systems- In Stock!

BODYSHOP

WORKSHOP

WELDING

TOOLS

SAFETY

Navigating the World of MIG Braze Wire: An Expert's Guide

June 26, 2023 6 min read

A Closer Look at MIG Braze Wire: Facts and Functions

MIG (Metal Inert Gas) braze welding wire is a type of filler wire used in the MIG brazing process. MIG brazing is a welding technique that combines elements of MIG welding and brazing to join metal pieces together. It is commonly used in automotive and sheet metal applications.

MIG Braze welding wire is being used more and more in modern automotive design in places utilising AHSS, UHSS and galvanised steels. The general theory is that it has a lower temperature melting point than steel and so it doesn't change the molecular structure of the steel while joining it. It also doesn't vaporise the galvanic layer around the weld pool, therefore providing an anti-corrosion joint.

MIG Brazing is performed by MIG - MAG welding machines and a copper silicon welding wire to bond the materials together. It can be welded using ordinary transformer welding sets or preferably with inverter pulse synergic. (see pulsed welding)

WHY DO WE USE MIG BRAZE

- Copper silicon welding wires melting temperature is typically 900 degrees Celsius compared to steels 1900 degrees.

- Stronger weld strength than steel welding on thinner steel panels.

- Doesn't change the molecular structure of the steel.

- Its a glue, not a weld!

- It's possible to leave the Galvanising layers intact to the rear of the panel, keeping panel rust integrity intact.

- Less distortion to panels.

- Relatively spatter free!

- You can join dissimilar materials.

MIG BRAZING WIRE

The main type of Mig brazing wire used in automobile repair is:

C9 MIG Brazing Wire CuSI3 EN 24373 Cu 6560 (Cu Si3 Mn1)

This is the most popular wire used for welding galvanised steel body panels. It has a melting point of ºC: 980 ( steel has a melting point of ºC: 1900)

Manufacturers Recommend:

- Pulsed welding 1.0mm wire.

- Dip transfer 0.8mm wire

CAN YOU BRAZE WITH A TRANSFORMER MIG WELDER?

The short answer is yes you can, But it's not so simple. MIG braze welding wires have a lower blow characteristic compared to steel wires, this means they require less voltage than conventional steel transformer welders can produce.

MIG braze welding voltages start at about 10V for 0.8mm and finish at 16v.

At 16v we would be welding very hot, and the possibility of overheating the brazing wire (turns dark) is significantly increased.

A conventional bodyshop transformer MIG welder on setting number one would have a typical voltage of 15V meaning we are near the maximum voltage for 0.8mm wire. Therefore to keep heat in the pool to a minimum, we would need to turn the wire speed down and weld very quickly to reduce panel distortion.

MIG Brazing wire has a large arc current band compared to steel welding wires.

For a set voltage, it is possible to move the wire speed from very low 30 amps to 100 amps, just by increasing the wire speed. You can't do that with steel as the band is a lot tighter.

WHAT GAS IS USED?

Pure Argon gas is the standard gas recommended for MIG Braze welding as it allows the weld pool to flow without the gas adding any extra heat other than melting the wire. Pure Argon also is required if you want to pulse weld brazing wires using a Synergic pulsed inverter MIG as recommended by Vauxhall Opel.You can also use Argon 5% for MIG brazing. This introduces some Co2 and Oxygen into the weld seam, making it hotter in the seam and a more barrelled bead appearance. It's ideal for BUTT Welds but cannot be used for LAP, SLOT or PULSED welds.

WHAT PANEL JOINTS ARE RECOMMENDED?

BUTT WELDING

Butt Welding quarter panels requires special techniques to weld correctly without distortion occurring to the panel.

The following is when using pure Argon gas

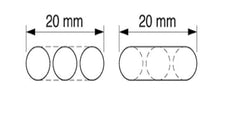

- Firstly ensure the panel gap is: TWICE THE SIZE OF THE WELDING WIRE as this enables you to push the weld pool to the back of the panel leaving less of the weld to grind down at the front.

- Weld using the short arc process as this enables easier placement of the pool. Weld in spots! very short and sharp Weld each spot edge to edge as the pools will capillary together.

- Weld slowly to reduce heat input into the panel and to keep distortion of the panel to the minimum.

The following is when using pure Argon 5% gas

- If you use Argon 5% for butt welding, the gap and the weld can be performed exactly the same as when welding with steel. The extra heat produced in the weld seam from the gas enables it to penetrate and flow to the rear of the panel more easily.

- Remember though it also creates more heat and so distortion or blowing holes could now be a problem.

SLOT WELDING

Pulsed mode is preferred for welding slot welds as the pulsed action gives better capillary action and more heat is enabled in the weld pool, so giving a stronger weld.

MIG Brazing an 8mm hole like when plug welding in steel doesn't allow for enough heat to be transferred to the pool seam creating a weaker weld joint.

Increasing the weld size too 10mm doesn't help either and thats why slot welds are used as the length of the slot enables greater heat to build up in the seam and so make a stronger bond.

Therefore there is no PLUG WELDING when MIG Brazing.

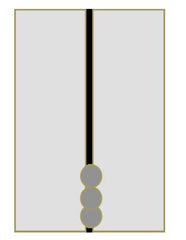

Special tools are available to punch out the slots or if this isn't available, simply drill three drill holes and join them together.

One Slot = One Spot Weld = One MIG Plug Weld

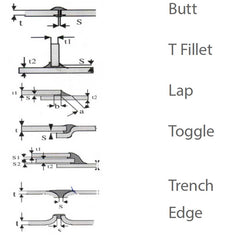

APPROVED JOINTS

Above is a diagram showing all the different types of joints that can be used. The butt or groove joint is the hardest to achieve and requires good technique.

CAPILLARY ACTION

MIG Braze flows using capillary action, it therefore flows into the joint.

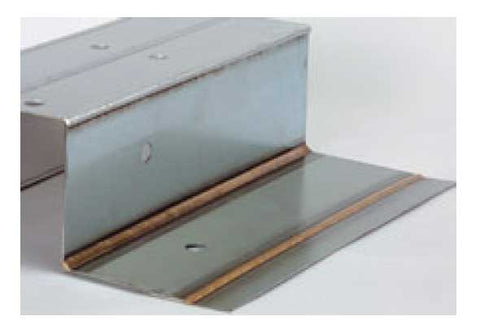

As you can see from the above MACRO, the steel doesn't melt of fuse. The molten Braze flows around the joint and this is what gives it its strength. You can also see if don correctly the original steel in the joint doesn't get too hot, so keeping its molecular structure and strength.

PULSED WELDING

Pulsed or dropule welding is a process where the welding wire does not touch the material during the weld but transfers onto the material in droplets.

It's a bit like somebody squeezing molten drops onto the job with an eyedropper. This gives a smoother, flatter weld with less spatter and reduced chance of blow through on thin panels. There is also less contamination of the welding wire during welding.

Pulsed welding is basically a modified Spray Arc and is due to the inverter being able to switch quickly from lower to higher voltages quickly. Each time the higher voltage is achieved a small molten droplet of wire is produced. This process can happen up to 30 times a second.

It's excellent for the MIG Brazing of slots and laps as being a liquid it falls flatter on the panel, giving a better bead appearance than with dip transfer.

WELD ANGLE

The correct weld angle for MIG Braze is critical to ensure the right bonding effect. To Weld correctly imagine you want to push the Weld in between the joint as shown below, this will reduce the weld bead height and allow the braze to flow into the joint.

MIG BRAZING In dip transfer mode has a smaller weld pool when compared to steel welding its therefore easier to jump out of the weld pool if the torch angle is too steep as you push it down the joint. If the wire does come out of the pool, spatter will be observed as the arc has to reistablish again.

Always weld at a torch angle of 60/90 degrees.

CONCLUSION

MIG Braze welding has many great features for repairing automobiles.

- It is doesn't suffer from cathodic corrosion (non-rusting )

- It's stronger on body panels less than 1mm in thickness than welding with steel wires.

- It helps maintain the galvanising layer on the body panel due to the lower melting temperature.

- It doesn't change the molecular structure of the body panel when welded.

The one downside to MIG Brazing is that doesn't show heat, or blow holes as steel welding does; therefore, the welder can weld too much at any one time, and this increases the chances of distortion in the body panel.

Technicians can also have a tendency to grind too much of the weld for appearance purposes, and this reduces its strength.

Grinding can also magnetise MIG Braze, which is another problem to be avoided.

Credits

The TWI ( Welding Institute)

Leave a comment

Comments will be approved before showing up.