Your Cart is Empty

Need Some Help? 0161 223 1843

Need Some Help? 0161 223 1843

BODYSHOP

WORKSHOP

WELDING

TOOLS

Boron Awareness- Why Do We Weld?

September 22, 2020 7 min read 2 Comments

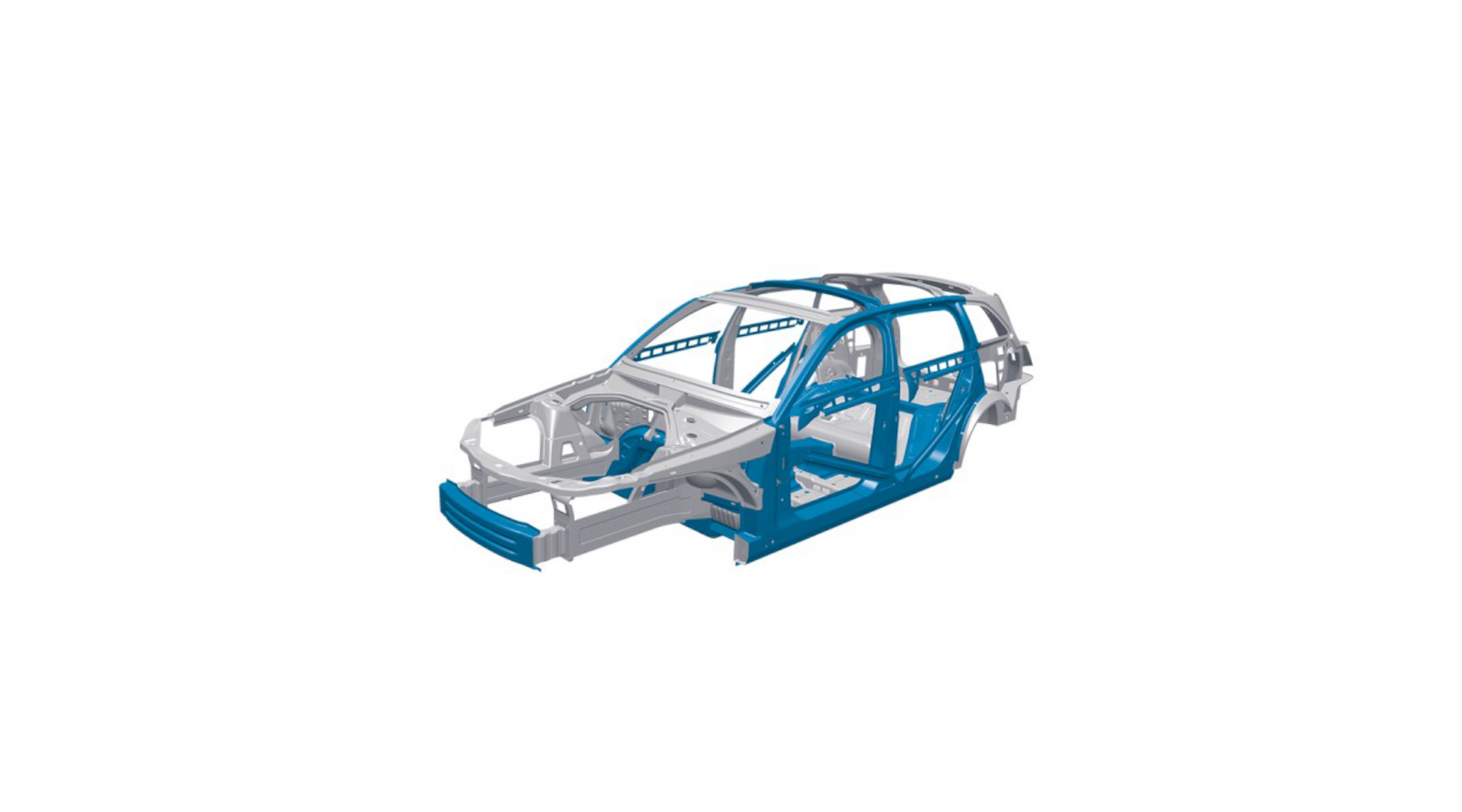

The automobiles that we see on the market today have changed significantly over the last 20 years, due to the need for stronger structures in the event of an accident whilst also reducing weight due to meet carbon emissions laws, has necessitated manufacturers looking beyond conventional, to more specialised types of steels,

BORON STEEL

In the late 1990s, manufacturers such as GM and Volvo started introducing body shells with a new alloying element. It was called "Boron", a common element in the earth's crust that increases its hardness when added to carbon steel.

This alloying element, coupled with the cold stamping presses used in manufacture for making thin car body panels creates a robust and stiff panel with a high yield point.

The type of Boron Steel used on vehicles today has exceptionally high strength. The type utilised on Volvo cars has a yield point of about 1,350-1,400 MPa (196,000-203,000 psi), that's about four times stronger than average high-strength steels. The process used to make it these steels hard takes away some of its workability properties, such as straightening it once deformed.

Typical applications of press-hardened steels

- Hot-stamped A-pillar

- Hot-stamped B-pillar

- Hot-stamped door ring

- Hot-stamped front / rear side member

- Hot-stamped cross members

- Hot-stamped tunnel

- Hot-stamped seat cross members

Boron steel gained an almost mythical status among panel technicians, as an air saw wouldn't cut it, and HSS spot drills wouldn't drill it! Not being able to section or remove the panel created confusion among technicians in the dark about these new steels.

They also then believed Boron was the "only" type of new steel used, and presumed, if they could drill and cut the panel, that it must be "normal" steel and so repaired as usual.

Precisely because of this training was implemented by the IMI, so technicians understood these steels and repaired responsibly. Subsequently, they had to attend "Boron Awareness" courses to understand these materials and how a vehicle chassis frame was manufactured.

ULTRA HIGH STRENGTH STEELS

Boron is a UHSS (Ultra High Strength Steel) and is part of the Martensitic family of steels (graph: MART). There are many grades and names of this family of steels and Boron is but one. Martensitic steels are characterised by their strength and not being very flexible. Therefore, it is not easy to press them into extreme shapes and curves. They are found in strengtheners located behind other panels.

Martensitic Steels, though, are severely affected by heat during repair and, if overheated, lose their strength characteristics.

ADVANCED HIGH STRENGTH STEELS

Most commonly used are HSS, DP, TRIP and TWIP which are labelled Advanced High Strength Steels (AHSS). TRIP and TWIP are types of what is commonly known as "plasticity steel". These steels have a certain amount of flexibility for machine pressing, but a hardening characteristic in the event of an accident.

AHSS steels give the designer lots of options to make the vehicle lighter but, also, stronger and stiffer - all this while reducing the steel sheet thickness!

Modern vehicles can contain many steels, not just one or two as before this can make repair difficult for the technicians.

Engineers need to understand that panels are thinner because of their special characteristics; and so, need to repair them according to what manufacturers advise. This means many repairs cannot be done without guidance and Vehicle Manufacturers Repair Methods.

A lot of these new steels are affected by excess heat which weakens the steel and, consequently, the weld quality (i.e. welds breaking under vibration). Some steels can be welded as normal, some require MIG Braze, and some cannot be welded at all - but all steels require correct fitting to maintain their special structural properties.

CRASH RATING

The crash rating is the goal manufacturers work to in order to sell vehicles in the Euro zone and so it is now the go to standard.

The vehicle pictured above shows two vehicles performing a Euro NCAP crash rating test. The white vehicle only manages a crash rating of 3, utilizing older, weaker technology. The red vehicle achieves a crash rating of 5 and utilises the New UHSS and AHSS steels. The red vehicle's safety cell has provided much better protection for the occupants, potentially saving one or more lives in a real-world crash.

The job of a technician is to ultimately return the vehicle back to this state after repair so that it retains its crash rating in the event of another crash.

CAN YOU WELD BORON or UHSS?

ANSWER - It depends on the process and the heat applied.

MIG MAG welding of Boron is a big no no. The heat generated in the welding pool is far in excess of that allowed for Boron steels. The HAZ (heat affected zone) that is around your weld is weaker than the weld bead and the material. It is In this area that it can fail in a subsequent crash.

The panel you are putting on is NOT boron or UHSS steel, its of a lower grade. The strengthener panels tend to be replaced as a whole and sectioning criteria for repair would mean sectioning the old panel away from these strengtheners so that you do not damage them.

If you were to cut through an outer panel and slightly scratch or cut into the Boron below this would create a fracture point as the Boron steel is extremely hard and as such brittle.

Therefore if repair is allowed and you are joining your panel TOO Boron or UHSS steels a lower temperature joining method is preferred. These include:

- Spot welding

- MIG Brazing

- Bonding and Riveting

RESISTANCE WELDING

Spot welding is a particular concern in the industry as it is easy to set incorrect welding parameters and overheat the weld. The welding nugget and burn ring criteria must be carefully observed.

The first generation of inverter spot welders had 9000 amps and, typically, 200 Dan of welding pressure with an X type gun. This pressure is only sufficient to control 7000 amperes of current unless the welding time is sufficiently increased.

AHSS steels need to be welded with shorter welding times and higher welding currents. This use of a higher welding currents requires the gun to achieve higher electrode tip pressures to control the weld.

C type guns can achieve this pressure easier than X type guns, when welding over large areas such as rear panels and so are the preferred approach for AHSS steels.

Using X type guns over rear trunk panels can cause problems - the pressure drops significantly because of the arm length, and so, heavy splash out and weld fracture can be observed. If you only have these types of welders, then we would recommend using MIG MAG welding for the repair of these panels instead.

Using X type guns over rear trunk panels can cause problems - the pressure drops significantly because of the arm length, and so, heavy splash out and weld fracture can be observed. If you use these types of welders, we would recommend MIG MAG welding of the panel instead.

NUGGET DIAMETER

Many new vehicles now have larger weld nuggets compared to older mild steel vehicles. This is because of the nature of the steels and its resistance. UHSS and the new Alloy Steels have lower resistances to current flow when compared to mild steel. This makes them harder to heat up and also more difficult to spot weld, this is why spot welders have been getting bigger whilst vehicle panel thickness has been getting less.

This lower resistance also causes a problem called "shunting", this is where the electricity would rather travel through a previous weld or shunt than through the area you are trying to join. This can weaken your weld as well as the one performed previously.

Larger gaps are then required between spot welds and so this means fewer spot welds per panel, hence welds now are larger than before.

A typical welding parameter for an 8mm welding nugget diameter on 0.9mm AHSS steel requires a welding current of around 10000 amps and a pressure in excess of 380 Dan. So, as you can see, larger welding guns and more powerful welders are required to weld these steels very quickly and keep the HAZ (Heat Affected Zone) to a minimum. When instructing, we often explain this heat problem by referring to water in a kettle ie: if you boil it for too long, the water will evaporate. In essence, the same effect can happen in the weld nugget if you weld too long .

Always observe your spot weld and adjust as necessary, so called "smart welders can help but they are no substitute for a technician observing the weld. Read our post on "are smart spot welders really smart!"

WELD TESTING

The only way to ensure a spot weld is good is to “Destroy It!”. To do this we do spot weld tags, we then measure the spot weld size and compare it to the manufacturers size on the vehicle. Please see our post on how to do a a peel test Here.

We would recommend doing weld tags BEFOREwelding to ensure correct welding parameters for the vehicle to be repaired.

MIG BRAZE WELDING

MIG BRAZING

MIG Braze welding is a bonding process, the heat produced isn't high enough to melt steel and so "bonds" to the surface. It has a capillary action in that it spreads out to areas that have been heated. Its lower melting temperature means it can be used by manufacturers to join UHSS steels. An example of a Braze Seam is shown above from a vehicle manufacturers method sheet.

MIG Braze welding though is still a heat process and as such you can still damage the UHSS panel by over welding the joint. Heat builds up, and so the more welding you do at any one time means the more heat is produced on the whole of your panel.

Always be aware of this heat and do not perform to many welds quickly at any given time.

MIG Brazing is an arc process and so it can be performed using normal transformer MIG welders but be aware, the heat generated by these welders can easily mean you have overheated the weld seam, this is why synergic inverter welders have come to the fore as they offer easy programme selection of parameters.

See our post on "How to MIG Braze vehicles " for more information.

REFERENCES

https://www.totalmateria.com

Thatcham Methods

2 Responses

Brian McGoldrick

February 13, 2023

good information would definetly recommend

Leave a comment

Comments will be approved before showing up.

Carl

August 10, 2023

Good useful information,

Every person repeating should read this !

There should be a lot more information about welding and straightening mixed steels cotinga & glue preparation.

I see a lot repairs that people have done that are wrong & would & do fail because they repairs cars in 80,90 2000 still using old welders & heat oblivious they are doing it wrong. Do please make as much info available