NEW Glue Pulling Systems- In Stock!

NEW Glue Pulling Systems- In Stock!

BODYSHOP

WORKSHOP

WELDING

TOOLS

SAFETY

What Does Duty Cycle On a Welding Machine, Mean?

October 17, 2019 3 min read 2 Comments

Duty cycle in its shortest explanation means how long a welding machine will weld at a given current before it over-heats. A machine with 300@ 60% will give an output of 300 amps for 6 minutes before overheat. A cooling or rest period maintained for 4 minutes must then be observed.

The European Directive EN 60974-1 states that the time period for one complete cycle is 10 minutes.

Duty Cycle is a term often spoken but never really explained. Most people when purchasing a welding machine are unaware of what the term "duty cycle" means, they just look at the large numbers printed on the side of the machine. Manufacturers know this and so can be a little disingenuous in how they label equipment.

Duty Cycle is listed on the machines data plate and usually, you will see 20-25-30% 60% and 100%

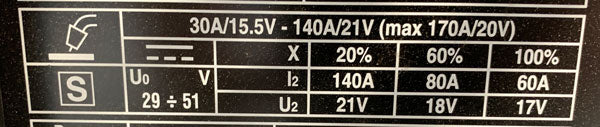

Let's look at a welders specification plate and what it means!

Below you will see the relevant current reading for this 180A labelled welding machine.

At 60% the welder produces 80 amps, it means that this welder will weld for 6 minutes at 80 amps in an ambient temperature of 40 degrees before it overheats.

This is the number you should compare when looking at different models of welding equipment.

Reading A Specification Plate

The specification plate gives you lots of interesting information so being able to know what it means is important so that you don't buy a machine that doesn't fit your needs.

The symbol on the left denotes a MIG MAG welder and so the readings relate to this process. Notice also that this welder has duty readings for 20%, 60% and 100%

|

U0 |

Is the welding voltage band from low to high. 29 to 51volts |

|

X |

Duty Cycle Percentage ( always choose 60% as a guide) |

|

I2 |

Tested current output (welding) |

|

U2 |

Tested Voltage output (welding) |

Another really interesting number to look for is above the duty cycle readings. As you can see it shows 30A/15.5V. This is the lowest voltage and current setting of the machine. The 15.5V is especially important if you want to weld thin cat body panels. A welding machine with a higher voltage here may prove more difficult in welding these panels. Some of the best body shop welders have a voltage of 14.7V

Multiprocess Machines

If a machine is multiprocess then it will show duty cycles, OCV (open circuit voltage)

and mains supply for each process.

as shown below.

As you can see it shows readings for MMA, TIG and MIG MAG.

If you look at the top left corner you can see the symbols for a single-phase Inverter.

Machine Designation Symbol

This is usually on the top left-hand side of the plate, it shows the type of machine as tested.

The picture below shows that this machine is a single-phase machine with DC output.

The two circles denote a transformer. A 3 phase machine will say 3~

Input Supply Information

nput Supply Information

The U1 reading says the machine supply voltage. The I1 max is the maximum welding current the machine will draw at its maximum setting from the mains supply.

This is important if you are going to run the machine correctly at a high output or maybe on a generator.

The European norm EN 60974-1 states that welding power sources should be capable of delivering their rated output when the ambient air temperature is within the range of -100C to +400C. Most Quality machines are tested at 40C although some may be tested at 20C to try and improve the duty cycle rating. Again try and be aware of this when comparing machines with each other.

Also because of different ambient temperatures in different countries (especially in colder climates), it could take longer for a machine to reach its working temperature so that the thermal trip can come into operation.

So what have we learned?

- Observe the 60% duty on machines to get a true reflection on its capabilities.

- Observe the I1 Max setting for machine current draw and correct mains installation.

- Observe what your welding machine is going to be used for and pick the correct duty cycle for your needs.

- Speak to a welding engineer if you need advice.

2 Responses

Syndicate Welding Services

July 08, 2022

Hello

Thanks for sharing the great information. I read this blog and must say the information that you shared in this blog is really very useful. Please post more blog related to " Top Mobile Welding Company in Canada"

Thank You.

Leave a comment

Comments will be approved before showing up.

David

September 21, 2024

Certainly gave me something’s to consider.