Your Cart is Empty

Need Some Help? 0161 223 1843

Need Some Help? 0161 223 1843

BODYSHOP

WORKSHOP

WELDING

TOOLS

The Best MIG Welder for Aluminium Car Bodywork

November 13, 2019 7 min read

What is the best MIG Welder For Welding Aluminium Car Body Panels?

It really applies to what features the welder has that enables you to weld it more easily. So let's look at the problems we have welding thin aluminium and the machine features that are required for us to weld it!

Then when you are looking for a welder you will know what functions and features it must have.

Aluminium

Pure aluminium (Al99.5) is not very strong. However, it is used as the basis for alloys in vehicle aluminium with a strength that can match up to steel.

Vehicle aluminium alloys are particularly difficult to weld due to their thinness and so they require special welding procedures and equipment to weld them correctly.

Welding aluminium is also particularly difficult because the material is surrounded by an oxide layer. This only melts at around 2015 degrees Celsius, while aluminium itself melts at around 650 degrees depending on the alloy. If the oxide layer were to be melted in a conventional manner then the aluminium would run away, and welding would be impossible. It is, therefore, necessary to destroy or displace the oxide prior to welding.

Aluminium as a material also has a special characteristic in how it heats up that differs it from steel. Steel localises its heat and it spreads out from the centre enabling you to create a weld pool easily. Aluminium is the opposite. When you arc up the heat generated travels great distances from the area of the weld and so it takes longer to generate a weld pool. This is called Cold Start and is one of the main features that make welding vehicle aluminium particularly difficult.

Vehicle aluminium alloys are particularly difficult to weld due to their thinness and so they require special welding procedures and equipment to weld them correctly.

Here we go through some of the problems and some of the welding machines features required to overcome these problems.

Transformer or Inverter

Transformer step switched welding sets can perform aluminium welding they just make it more difficult. Transformer units tend to have large voltage steps between settings ( 3-5 Volts) and so a weld could be either too low and the next setting too high.

Inverters generally allow fine voltage adjustments and so the optimum voltage for what you want to weld can be achieved.

Transformer machines tend to have a fixed "choke" and it is usually set for steel or hard wires. The choke performs a critical function in that it slows the sudden surge of current when the wire shorts on the material so that the explosion is not too fierce.

On thin materials, you require more choke and on thick less. A transformer machines choke is generally set for the middle welding range of the machine so you may find it too course down low. The choke as I say is also set for hard wires, the choke required for soft wires like aluminium is different its a lot softer. Welding aluminium with a steel transformer MIG may mean the arc explosions are very fierce and create excessive spatter.

An inverter, on the other hand, has an electronic choke and this is set to the optimum setting for the wire and material to be welded. This gives smoother welding with less spatter.

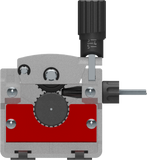

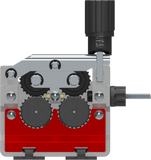

Two Roll Four Roll

The Wire-feed is critical when welding soft wires. 4 roll wire feeds are a necessity as they allow easier feeding of the wire through the torch. That's not to say you can't feed soft wires with 2 roll wire feeders, it just makes it more difficult.

Dip Transfer- Short Arc

“Dip transfer” or “short arc” are the terms used for the standard welding process we all know and use daily.

The welding wire is essentially a mains fuse and when this fuse is “shorted” to the material a surge of current is detected at the pinch point ( The welding wire sticking out of the tip).

This current steadily rises until the wire explodes.

The size of this explosion and the length of wire blown off is determined by two things.

- The diameter of the wire.

- The voltage selected on the welder

That would be it if it wasn’t for the wire feed immediately replacing the wire and causing a “short again”.

This happens 50 times a second (60 In USA) due to the frequency of the mains supply 50Hz.

Once you match the length of wire hanging out of the tip to the number of explosions then you reach resonant frequency (the crackly bacon noise we are all familiar with).

To make a bigger explosion, you turn up your voltage and then tune your wire in again till resonance is achieved. And so it goes.

There is a problem with the “short arc” action on thin materials, and that is when the weld pool is developed the wire to keep blowing must “dip” into the weld pool to explode. This dipping action is much like a needle popping a balloon and so it’s easy to blow holes in thin materials.

To overcome this, welders perform a tack or pulsing action to reduce the amount of heat in the weld pool and stop from blowing holes.

This action if not Performed correctly can produce welds with a lack of penetration. Even in thin materials.

So welding thin aluminium in Short arc mode is very difficult, you could try tack welding it but as we have stated this creates a cold weld pool and so the bead will not develop correctly.

As a rule, Short Arc welding CANNOT be attempted unless the material to be welded is twice the thickness of the welding wire due to “cold starts”

Pulsed Welding

Pulsed welding is sometimes called "dropule" or "free flight" welding.

The electronics inside the machine allow for the pulsing of the welding arc from dip to spray and this causes a dropule to be formed.

This heating and cooling of the spray arc process creates droplets much like an eyedropper squeezing liquid onto a surface.

This droplet has many advantages over the dip transfer process.

- Creates less spatter

- Allows for thinner materials than the wire diameter to be welded.

- Reduces cold starts.

- Gives improved weld appearance and quality.

- Allows for faster run speeds.

Double Pulse

Double pulse is a function on most high-grade Pulsed inverter welders. This function enables the weld pulse to be switched on and off automatically. This creates the "penny stack" or "herringbone" weld appearance to the weld bead as shown.

Double pulse also helps when welding thin aluminium in that it reduces the amount of heat into the material. For every hot cycle, there is a cold cycle. The welder simply stays when the pulse is on or hot and moves when it's off or cold.

Synergic

Another advantage of "Pulsed Inverter MIG Welders" is the fact that they are SYNERGIC.

Synergic means a one-button operation. Programmes have been inserted into the machine with the optimum weld settings for a given materials thickness. The synergic operation of the machine makes it easy to use even for relatively new and inexperienced welders.

These synergic programmes enable fast single knob selection of the optimum setting for the material you want to weld. This gives the welder less to worry about when setting up the machine and so can just concentrate on laying down a good bead.

Hot Start and Crater Fill

These are functions performed by the welder at the start and the end of the weld when welding aluminium.

It's difficult when you start welding on aluminium to get a hot pool. This means that the first 20mm of your weld could be sat on top of your material and not melted sufficiently. This is called "Cold Start".

Hot Start

To combat this some machines have the option of hot starts. This is where the welding current is spiked up for the start of the weld to enable you to get a liquid pool easier and penetrate your material. This function can either be automatic where the machine welds high for a couple of seconds then drops to the selected welding current automatically. The other way is to control this by trigger function on your welding torch.

Either way, this is a necessary function required for good aluminium welding.

Crater Fill

There is another problem with aluminium welding in that when when you come to finish your weld the heat is pulled from the pool very quickly and this can cause a crater or crater crack to form in the weld bead. This is undesirable as its a weakness in your weld. To overcome this, many pulsed inverter welders have a crater fill function when you release the torch trigger at the end of your weld. Very simply it reduces the welding current while still feeding the wire into the weld pool. This fills your crater.

So what is the best welder for welding aluminium on cars? The answer is really down to what functions and how smooth the arc is on your chosen welder but below is my must haves. Another consideration may be manufacturers approvals, in Europe the FRONIUS 270I is one of the most approved welders on the market and therefore would be a good place to start.

Features and Functions Required for the Welding of Aluminium on Automobiles.

- Synergic Inverter Pulsed Welder.

- Four roll wire feed.

- Max Welding output of 250-300 amps

- Hot start and crater fill function.

- Synergic programmes

- Optional water cooling**

- Double pulsed function

- Manufacturers approvals

** In order to create the dropule when pulsed welding the machine needs to peak over 250 amps for each dropule, this can overheat air-cooled torches if performing long welds. Therefore water-cooled torches may be required.

If you have any enquiries or are requiring further technical advice please don't hesitate to contact us using the following link

With thanks to

Cooptim Mechanics

Weldreality

Leave a comment

Comments will be approved before showing up.