Your Cart is Empty

Need Some Help? 0161 223 1843

Need Some Help? 0161 223 1843

BODYSHOP

WORKSHOP

WELDING

TOOLS

The Best MIG Welder for Beginners in the UK: A Comprehensive Guide

February 17, 2024 10 min read

Buying A MIG WELDER GUIDE

Buying a MIG WELDER can be a daunting task as there are so many to choose from and lots of considerations to take into account before you spend your hard earned cash . So let's look at the things I would look for when choosing the best welder for welding in a bodyshop, home/workshop for the repair of vehicles.

Factors to Consider When Choosing a MIG Welder For Beginners:

- Amperage (AMP) that you will need. What thickness are you welding?

- 240V single phase or 400V three phase, you decide?

- Always choose a MIG Welder with a Quality Wire Feed.

- MIG Torch connection. Euro adapter Torch or straight in?

- MIG Inverter or traditional MIG transformer?

- Carry around (mobile) or Workshop.

- Warranty period.

- Your Budget/Price.

Amperage (AMP) that you will need. What thickness are you welding?

This is probably the biggest decision you will need to make as it will also affect your price. The higher the amps a welder can supply then basically the thicker the material you can weld. Welders get more expensive the more amps they can supply. Transformer units obviously need bigger transformers to give you those extra amps and that is going to cost more. Inverter welders require larger electronics such as IGBTs and Semipacs and so again it will cost more. Look at what you mainly require if for and choose the best duty cycle welder you can afford in this range. What does duty cycle mean on a welder?

BUDGET

This is the big question? You would be surprised but you can get some really good MIG/MAG welders for surprisingly small amounts of money today. You can also blow your wallet on the highest specification, with most of its functions you probably won't use.

Set a budget that is reasonable and includes most of the points we will go through here.

FAVOURITE MIG

Transformer Welders have been around for many years, the Old ARO 2022 is what I started with when I first became an engineer and its still my favourite MIG even though it was built 35 years ago. Many of its features that made it a success in the bodyshop, are still required today and are what you should be aiming for when looking to buy,

It was a step switch transformer MIG MAG with Synergic wire feed settings. making it a simple machine to weld with and it was loved by bodyshop technicians. It also had the unusual thing of a handheld spot welder on top. This was the part that broke down the most due to heat and overuse. Slowly a lot of shops removed these as new spot welders came on the market but there are still a lot of the MIGS in constant use today.

SINGLE PHASE OR THREE PHASE?

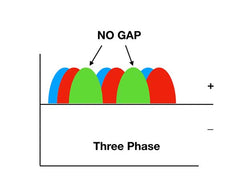

Obviously, in your home workshop or garage, you will have no choice but to choose the single-phase Mig welderbut to get the best from a transformer MIG MAG welder you really need a three-phase MIG.

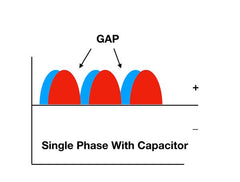

The rectifier cuts off the negative part of the AC wave to create DC inside the welder, a single-phase has gaps in the wave three-phase welder doesn't. This you will feel in smoother welding.

To compensate for the gaps in a single-phase welder we use capacitors (the red in the single-phase drawing). The better the capacitors the smoother weld is. Cheaper hobby type welders may not have capacitors in them making the arc quite course especially down low.

So if you cant have three-phase then choose a MIG with good capacitors for a smooth arc. ( or pick an inverter, more about that later)

Look for welders that can be plugged into a regular 240V power supply.

If your a hobby welder or even a small garage then a 230V welder is the obvious choice. Choosing a 240V MIG Welder just means its supply voltage and this can also be shown as 230V. Most will work in a standard UK 240V plug and if you are only doing light welding then you will find this is more than adequate. The higher you go up in Amps the more current you will draw from the supply and so it possible that say a 200 amp MIG welder will run on the 13 Amp supply but will blow the fuse as your turn the welder up. This is because you will need a 16 Amp supply for the higher welding currents.

Choose a MIG welder with a Quality Wire Feed.

People always underestimate the importance of a quality wire feed and motor when purchasing a MIG welder for beginners. This the second most important thing after the power supply (transformer duty cycle) and its the one that always seems to get neglected, sometimes even by manufacturers.

Many times i have welded with a very good welding machine that has a very smooth arc to only be disappointed that the manufacturer has installed a plastic drive and motor

VOLTAGE

The old AROs main plus point was its transformer. It had a very low open-circuit voltage (15V) which was great for welding thin car body panels, it also had many settings.

The more settings a voltage switch has the smaller the jump in voltage between settings. There is nothing worse than not quite having enough current then switching to the next setting to find we now have way too much. Picking a 180 amp MIG Welder with 6 voltage settings means the voltage jumps will be 3-4 volts between each. One with 10 steps would be 2-3 volts. This could be the difference between being useful for you when welding body panels or being too fierce.

So the more settings a welder has the smaller the jumps in voltage between the settings and the more useable a MIG will be.

This is where thyristor control welders came in. they have a lot finer adjustment of the voltage (typically 0.1v steps) as its electronic. This finer adjustment means you can pick the perfect voltage even for the thinner automotive panels.

So if you cant choose a thyristor controlled welder, pick a transformer MIG Welder with a low open-circuit voltage on setting 1 and many switch settings.

DUTY CYCLE

This really ibetween them n't important when welding vehicle body panels as you wouldn't normally get to the overheating scenario even on the cheapest welder. Welding a quarter panel on a vehicle will typically be done between 60 to 80 amps you would need to do a lot of continuous welding to cause the welder to overheat. See my post on What does duty cycle mean on a welder?

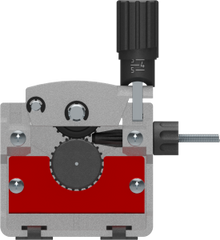

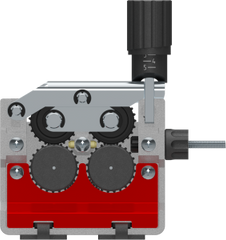

Choose a MIG welder with a Quality Wire Feed.

People always underestimate the importance of a quality wire feed and motor when purchasing a MIG welder for beginners. This the second most important thing after the power supply (transformer duty cycle) and its the one that always seems to get neglected, sometimes even by manufacturers.

Many times i have welded with a very good welding machine that has a very smooth arc to only be disappointed that the manufacturer has installed a plastic drive and motor

The wire feeds on smaller MIGs are essentially car washer bottle motors and are a bit rough. The drive rollers are a little spindly and thin all surrounded by bendy cheap plastic.

What does the wire feeder do? It needs to pinch 0.6 or 0.8mm of wire and push it 3 metres through a torch, a hot welding tip and into a weld pool. How good and how smoothlyit does it is important, the better the wire feeder the smoother your welding is. Two roll feeders are sufficient for hard wires such as steel but you really need 4 roll feeds for soft wires.

Choose the best wire feed system for your budget. Try it, see how smoothly it feeds and feel the quality.

WELDING TORCH

As we have just stated before for wire feed units, the torch is the main feed for the wire and it transfers the welding current so you can weld.

The length of the torch and size just depends on what wires you are using.

If you are welding with 0.6mm steel wire, the maximum length of the torch you can use is 3 metre. If you're using 0.8mm steel wire then you could go to 4 metres but again you could get wire feed faults unless you keep the torch straight during use.

Soft wires like MIG braze and Aluminium I would only recommend 3-metre torches.

For normal bodyshop use, BZL 150 type torches are all that's needed the 250 nozzle is just too large to get into places on a vehicle and is anyhow designed for gates and railings.

MIG Torch connection. Euro adapter Torch or straight in?

There are three types of MIG torch, direct fitted, euro adapted and manufacturer specific.

Directly fitted torches usually are lower quality and tend to have plastic or Teflon liners fitted inside. The steel wire cuts into the plastic liners, so sooner or later you will get wire feed faults. Once you start to get faults its a bit of a pain to change the liners.

Euro Adapter Torchesare a standard torch that is fitted to many manufactures machines. Euro adapted torches can be exchanged from machine to machine and the consumables tend to be standard Binzel (BZL) fitment. It is also easier to repair, change liners. and source spares. The torches also tend to be of a more professional standard.

They are connected to the welder via a euro adapter and this is standard through all euro adapted MIG Welders.

MANUFACTURER SPECIFIC

These types of torches tend to have their own manufacturers liners and consumables on them, this invariably means they are more expensive to replace, I tend to steer clear of these types of torches for this reason unless it actually makes the machine perform better.

I always look for euro adapter torch fitments when choosing a welding machine.

CHOKE SETTING

The choke is a very important part of MIG welding, remember we are essentially blowing a fuse and this is quite an aggressive explosion. This might be great and just what we need for fabrication but for vehicle welding, this explosion could end up blowing a hole in our panel. We, therefore, need to slow down the aggressiveness of this explosion and we do this with the aid of choke.

The better the choke the smoother the welding.

The main trouble with a choke in a transformer MIG though is that it is set by the designers for the optimum current of the machine (typically the middle setting). This could mean it's not quite smooth enough when welding down low, it's perfect in the middle and not enough at the top setting.

HOW LONG IS THE WARRANTY?

Always ask how long the warranty is for, and it it has a long warranty then what is actually included in the warranty. For example a manufacturer may warranty their MIG welder for 3 years but its actually the transformer that is applicable to. Th rest of the machine including pcbs is only 12 months.

WHY BUY FROM BWS?

Buying a welder from a company like us who have their own in-house engineers means that we can give you additional support and advice above what a manufacturer or company just selling a box can do. We may be able to repair your machine in-house quicker too meaning less downtime if anything goes wrong.

NEW REGULATIONS

From January 1st 2023 the European Union (EU) introduced Eco Design 2019/1784, a set of regulations designed to improve the efficiency of new welding equipment. This regulation aims to reduce energy consumption and improve air quality by encouraging the use of more efficient welding equipment. This directive applies to all newly manufactured welding equipment, regardless of size or type. It covers all stationary welding equipment, including electric arc welders, gas and plasma welders, and resistance welders. You can Read More about it HERE!

This new regulation will change how we ultimately purchase welding equipment as transformer units will slowly become obsolete. This doesn't mean you cant use them it just means manufacturers will not be able to sell them. Your choices then will change are we will be doing a post on what to look for when purchasing an inverter MIG welder.

Best Transformer 230v MIG Welder!

We believe that the Parweld XTE 201C is the best value and best made 230V MIG Welder that you can buy for the money. Prices start at a very reasonable £445 for the unit only and £520 for a package including torch regulator and earth. The Parweld XTE201C comes with a comprehensive 3 years warranty and its very well made. It feels well made also with a quality case that doesn't wobble and can take a proper gas bottle. It has a really good wire feed set up and good quality components inside. We have found them to be very reliable having sold many many units. The most important thing though is the arc, how it welds. Its been popular with car repair shops welding thin car body panels and has had great reviews from them. If your looking for a quality, traditional transformer compact MIG welder for home, hobby or small garage use then Buy the Parweld XTE 201C

Best 230v Inverter MIG Welder For Professionals/beginners.

The Fronius TransSteel 2200C is what i would call the ultimate MIG welder for beginners but its not cheap. The Name speaks for itself though with Fronius frequently being associated as the worlds best MIG welders. Its packed with quality features and components as you would expect and comes with a 3 year warranty. It's also available in 110-230v package If budget isnt really a problem and you simply want the best the get the Fronius TransSteel 2200C

Best 230V Inverter MIG Welder On a Budget.

If your on a tight budget and really want to get more bang for your buck the we wouldnt look much further than the Sealey Premier IMIG 160 Inverter MIG Welder Prices are around the £450 mark and it has some features only found in higher priced models. It has a quality wire feed for smooth welding and comes with a Euro Adapter so a professional Torch can be fitted. You can't go far wrong with Sealey Premier IMIG 160

If you need help or advice on what may be the best MIG Welder for you then please contact us either by Chat, Telephone or Contact

Leave a comment

Comments will be approved before showing up.