NEW Glue Pulling Systems- In Stock!

NEW Glue Pulling Systems- In Stock!

BODYSHOP

WORKSHOP

WELDING

TOOLS

SAFETY

What Is Spray Arc Welding?

February 18, 2020 1 min read

MIG/MAG WELDING: HOW IT WORKS-3

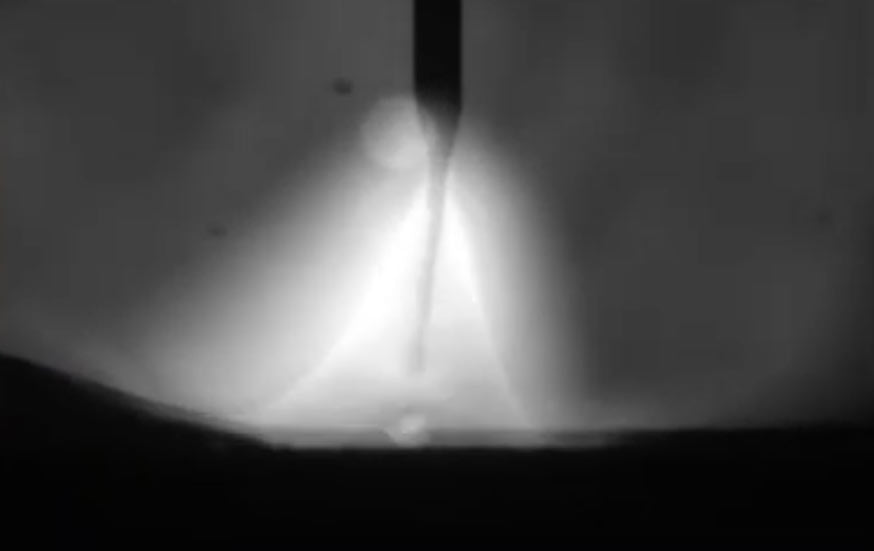

Spray or droplet welding is a type of welding where the welding wire doesn't short with the material (it doesn't touch). The plasma arc is so high that droplets about the same diameter of the wire used are melted and transferred onto the workpiece.

To create spray transfer you need to turn the voltage quite high as the spray is only possible at high currents (for the wire size)

|

Wire Size UK

|

Wire Size US | Welding Current |

| 0.6mm | 0.0236" | 135A |

| 0.8mm | 0.0315" | 150A |

To do this turn your voltage selector up and tune in your wire until you get the traditional crackle sound. Now back the wire off slightly until the crackle cannot be heard. The plasma is so high that each droplet is transferred to the weld pool in a consistent stream.

If a voltage that is too low to transfer the droplets is selected then the smooth transfer is not achievable and it becomes very erratic and "poppy" as it falls on the material to be welded under gravitational force

Spray arcs produce less spatter and higher run speeds so are desirable if the material thickness to welded enables it.

Therefore because you need this higher current to create the spray its is not possible to use on car body panels.

References

Video is from Fronius Welding UK

|

Paul Jones Director BWS Ltd, CSWIP Ive been a welding engineer for over 30 years and a welding inspector for 23 years with vast experience of welding and related topics. |

Leave a comment

Comments will be approved before showing up.