Your Cart is Empty

Need Some Help? 0161 223 1843

Need Some Help? 0161 223 1843

BODYSHOP

WORKSHOP

WELDING

TOOLS

The Best Spot Welder For Vehicle Bodywork

March 12, 2024 8 min read

What To look For When Buying a Spot Welder For car Body Repairs

Buying a spot welder is a big thing for a body shop, they can also be very expensive. Here I will go through what I think are important points to consider when purchasing. I will also explain some of the technical jargon that you will hear and what it means.

ITS CALLED RESISTANCE WELDING

Its the resistance in the joint to be welded that creates the heat and resistance welding consists of four things to make a weld.

- Electrode diameter

- Electrode force

- Welding time

- Welding power (amps)

The final consideration is the duty cycleand how many panel technicians you have.

THE REASON FOR INVERTERS

Inverter spot welding has been around for a very long time as was first introduced in the factories, on the production line. It enables high power welding to be produced quicker and with less heat than a conventional AC transformer welder.

This was critical when galvanised and zinc-coated panels were first introduced as it reduced the burn off of the coatings. It became even more important to weld with less time with the introduction of AHSS (Advanced High Strength Steels).

The main reason though, that the welders have got larger is due to the new alloys used in car manufacture. These alloyed steels have very low resistance and cannot be heated too much or they will lose their strength properties.

This is why spot welders have become larger but the steels have got thinner.

TRANSFORMER OR CABLE GUN

CABLE GUN

About 15 years ago, cable gun welders were the first type of inverter welder to be introduced into body shops, They invariably had X type welding guns fitted and the power output was 9000 amps. This output increased over the next few years until the ARO 13K Ergoweld peaked out at 13000 amps.

The main problem with these welders was they were reliant on the quality of the buildings mains supply as they required high mains input current. Some workshops could not achieve this, meaning they couldn't achieve the stated maximum current the vehicle manufacturers desired. This problem with supply started the movement by manufacturers towards transformer gun welders.

Next new EMF (Electro Motive Fields) legislation came in meaning the technician had to be protected from these fields as they are produced around the cables and gun when welding.

New machines with special EMF compliant cables were produced but slowly these machines died out for the manufacturer preferred transformer gun welders.

Advantages

- Guns were smaller and lighter.

- Some machines ( Aro 13K, GYS BPLXC ) had both X and C type guns.

Disadvantages

- Heavy mains supply draw.

- Couldn't achieve maximum stated output

TRANSFORMER GUN

Transformer gun welders have been around since the Invertaspot GT and Tecna Rhino about 10 years.

This meant that the machines now had only one C gun and much more control of the welding process. This is when the smart or automatic welder started to take off.

Advantages

- High welding currents can easily be achieved.

- Low mains supply current draw.

- More easily meets EMF regulations

Disadvantages

- The guns are very heavy, especially when using the large arm on rear panels.

- Over-reliance on smart control.

- Guns overheat more easily.

- Arms arc out a lot where they slot into the gun, damaging the gun and the welding arms.

RECOMMENDATIONS

Most manufacturers approved welders are now C gun transformer units and so you may have no choice but to choose one of these. The downside to these is that the guns are heavy and cumbersome when welding on rear panels. The best gun on the market is the GYS Genius and this is a C type transformer Gun with some great features such as electrode retraction and integrated water cooling into the electrodes. cable.

WELDING CONTROL

Most spot welders are now "synergic" with preset parameters and settings. Some are called "smart" or "automatic" and I have written a post about this before, which you can check out here.

No machine is automatic, no weld can be guaranteed, no spot welder is one-button operation. This is maybe, what you will be told by the salesman, but it's not correct in real life.

You will still need to sometimes weld in semi synergic or manual mode and this is what I look for in a welder. How easy is it to change from the automatic settings to the manual and can the pressure, time and power be adjusted easily.

RECOMMENDATION

I would purchase a welder with a clear screen that is simple to navigate. The control must be simple to move from the smart or automatic mode and into manual or expert mode.

WELDING GUNS

There are two types of welding gun "X" type and "C" type Most manufacturers (especially German) have moved to the transformer "C" gun option while the early bodyshop welders tended to be "X" type.

C TYPE SPOT GUNS

They have many advantages and some disadvantages:

Advantages

- Consistence pressure at the electrode tip even when welding over a rear panel.

- Welding action is front-on to the panel instead of side-on with an X gun. This can mean easier access and welding

Dis-Advantages

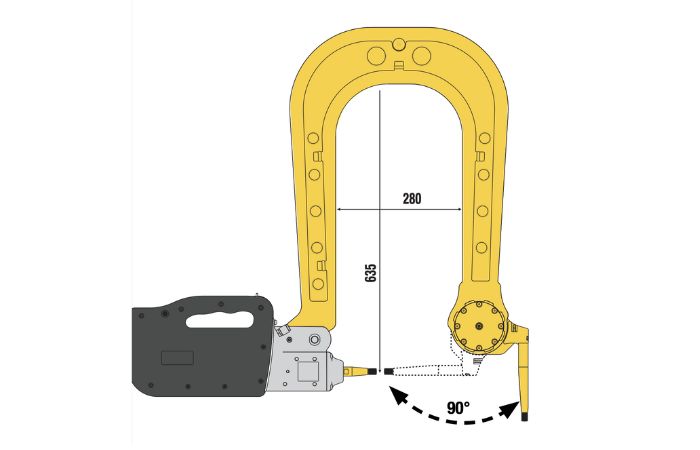

- The welding guns are heavy, some can be 40 kilos when the large 500mm "C" arm is fitted.

- C gun arm design is flawed when fitting into the gun body. This area has bad contact and can arc and pit both the gun and the welding arms.

- Cannot weld some panel flanges easily compared to an X Gun.

- Difficult to weld back panels if no piston retract option is fitted.

X TYPE SPOT WELDING GUNS

Advantages

- Can weld some panel flanges and hard to reach places more easily.

- Guns are slightly lighter than C guns as the electrodes tend to be thinner.

- Better design of the welding arms reduces contact arcing when placed in the gun.

- Most have a large opening or opening action to enable easier access over rear panels

Dis-Advantages

- Welding tip pressure reduces as arm length increases.

- Have to weld side on to a panel flange

RECOMMENDATIONS

You will need the good points of the X and C type guns in your daily work, therefore the perfect machine would have both of these guns. I only know of one machine that has this The "ARO Ergoweld" its an excellent machine but very expensive. Therefore our other options are the C Gun type Transformer welders. Here I would look at the quality of the gun, especially where the welding arms fit into the gun. I would then look at can these parts be replaced and what is the cost?

I would also look at how easy it is to weld a rear panel. Does the welder have an electrode retraction button to make access easier? Or does it have a special setup on the arm ( like the Shark arm by Telwin) to enable this?

If you have an older X type cable welder, I would keep it because you will still want to use it. Remember though, long electrodes on cable gun welders don't work, they have low-pressure at the tips, causing splash outs and possible weld fractures. These types of welders can only be used with shorter arms.

WELDING CONTROL

Most spot welders are now "synergic" with preset parameters and settings. Some are called "smart" or "automatic" and I have written a post about this before, which you can check out here.

No machine is automatic, no weld can be guaranteed, no spot welder is one-button operation. This is maybe, what you will be told by the salesman, but it's not correct in real life.

You will still need to sometimes weld in semi synergic or manual mode and this is what I look for in a welder. How easy is it to change from the automatic settings to the manual and can the pressure, time and power be adjusted easily.

RECOMMENDATIONS

I would purchase a welder with a clear screen that is simple to navigate. The control must also be easy to navigate out of the smart or automatic modes. Also being able to manually set the weld force (pressure) is a must.

ELECTRODES

There are a lot of spot welders on the market but the most popular size of electrodes are 13mm. There are some that are 16mm but these will create problems with location and access on the small edges of a quarter panel or sill.

I would, therefore, recommend 13mm electrodes.

DUTY CYCLE

This means how long something will work before it overheats. See my post on duty cycleto explain this. Its also important how many panel technicians you have.

I would recommend a maximum of three technicians per machine in a busy shop, any more than this and you will start to see the machine break down and require repair. Duty cycle is also a problem with the transformer C gun, especially in smart or automatic modes. These modes tend to weld three times longer than a manual weld and this causes the gun to overheat more. When we service a welder we carry out a 40 weld spot weld test to check this and see if the machine, gun and cooling circuit are working ok. I would suggest you do the same.

EMF (ELECTRO MOTIVE FIELD)

EMF is a magnetic field around a conductor when a current passes through the said conductor. The size of this magnetic field is dependant on the current.

The magnetic field also gets weaker the further you go from the conductor.

Transformer guns only have EMF from the welding electrodes forward of the main gun of the machine. It's quite large as the EMF is concentrated in this area.

Cable Guns produce less EMF as its over a larger area (all the welding cables and gun).

Transformers are larger and heavier so the operator will need to pull the gun closer to his body, also people tend to grip the welding arm again due to the weight. This means they are closer to the EMF and it's more concentrated.

The cable guns being lighter can be held further away from the body so the chances of EMF induced into your body are reduced.

EMF is not advisable in areas such as the head, spine and heart.

So transformer guns stand more chance of putting EMF into your heart as you tend to hold closer. Cable guns more the spine as people throw the cable over their shoulder. Both if they weld a sill section with the gun near their head.

So both have their pros and cons.

SPARE PARTS AND CONSUMABLES

Some companies pricing policy on spares can be a bit eye-watering. Checking the cost of servicing and consumable parts before a purchase is a must as the variation in costs can really add up over a spot welders life.

I had a customer call me once as one of his technicians had smashed the front LCD screen on their 6 month old spot welder.

Upon calling the company he was quoted £1600 for a replacement! After picking himself up off the floor he gave me a call and asked if I could source the screen.

After doing some detective work I located the screens from the original screen manufacturer in Taiwan and purchased 10 screens ( the minimum order). The total cost of all these screens including carriage was less than the one quoted to the customer from the supplier.

For some reason this ongoing cost is never taken into consideration when purchasing and yet is should. I would recommend before purchase to ask how much a new welding arm would be or a control PCB. Then you can compare this to another make you may be interested in.

TECHNICAL SUPPORT

For me, this is the most important part! Ensure the company you purchase from can repair and service your machine correctly. A purchase should be a long term relationship where mutual benefit is obtained. You with good service, parts cost and technical support. The supplier with extra business and a customer for many years.

If you need more advice and thoughts on a potential purchase, then please contact us and we will endeavour to answer your questions.

Leave a comment

Comments will be approved before showing up.