Your Cart is Empty

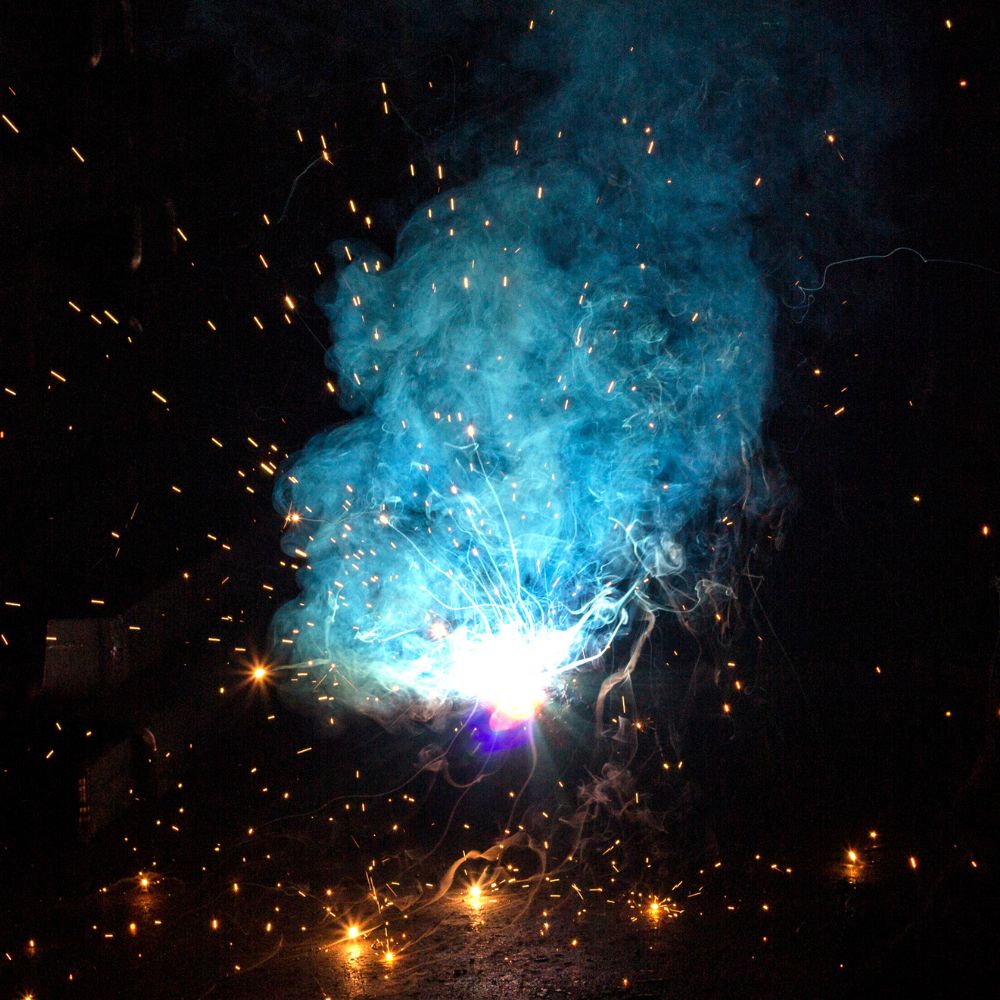

WHY HAVE WELDING FUMES BEEN RECLASSIFIED AS A HUMAN CARCINOGEN?

More!

t’s widely accepted that exposure to welding fumes can cause or contribute towards a number of health issues.

The UK’s Health and Safety Executive (HSE)says, for example, that welders are particularly prone to a lung infection that can lead to severe and sometimes fatal pneumonia. Many welders report flu-like symptoms commonly known as ‘metal fume fever’ and irritation of the throat and lungs is also prevalent.

WHY NOT USING A FUME EXTRACTOR WHEN WELDING, IS DANGEROUS?

More!

Welding Fume has always been known to be hazardous or at the very least an irritant, but now there is new evidence that even the lowest form of welding on mild steel can cause cancer,

Welders generally are a hardy breed and tend to not think of welding fume as a hazard, but it begs the question, why?

Enhancing Workplace Safety with Advanced Fume Extraction Solutions!

We at BWS understand the critical role of advanced fume extraction solutions in maintaining a healthy and safe working environment for welding operations. We have over 30 years experience in the welding and automation field The System we have chosen for you are designed to effectively capture and remove hazardous welding fumes and gases directly at the source, reducing the risk of respiratory issues and ensuring compliance with occupational health and safety regulations. Explore the latest innovations in fume extraction technology that offer improved efficiency, enhanced filtration capabilities, and ergonomic designs for seamless integration into any welding workflow. Learn how investing in the right fume extraction system can protect your employees, boost productivity, and contribute to a cleaner, safer workplace.FAQ

-

The latest fume extraction torches are specifically engineered to offer improved ergonomics and user-friendliness compared to earlier models. Extensive innovations have concentrated on minimizing weight and enhancing the ergonomic features and accessibility of these torches. Remarkably, certain modern fume extraction torches are lighter than regular welding torches without fume extraction abilities.

-

To ensure the well-being of workers and minimise air pollution, it is imperative to utilise welding fume extractors. These extractors effectively eliminate hazardous substances like metal oxides, nitrogen oxides, and carbon monoxide from the air surrounding welding operations. By adhering to strict safety measures, workers can be protected from potential health risks and meet the latest HSE requirements.

-

To meet the specific requirements of your welding operation, it's important to choose the right fume extraction system. Low-vacuum/high-volume systems are designed for larger capture zones, while high-vacuum/low-volume systems are better at capturing fumes close to the source. Assess factors such as available space and required air processing volume to make an informed decision.

-

When choosing a welding fume extractor, take into account factors such as the welding type, space size, pollutant type, and budget. There are options available for all scales of operations, ranging from flexible mobile units to large industrial static units that have automatic filter cleaning. Opting for the right extractor will guarantee a safe and tidy workspace while adhering to health and safety regulations.