Your Cart is Empty

Need Some Help? 0161 223 1843

Need Some Help? 0161 223 1843

BODYSHOP

WORKSHOP

WELDING

TOOLS

What is Dip Transfer Welding?

July 15, 2023 4 min read

MIG/MAG Welding: How it Works-1

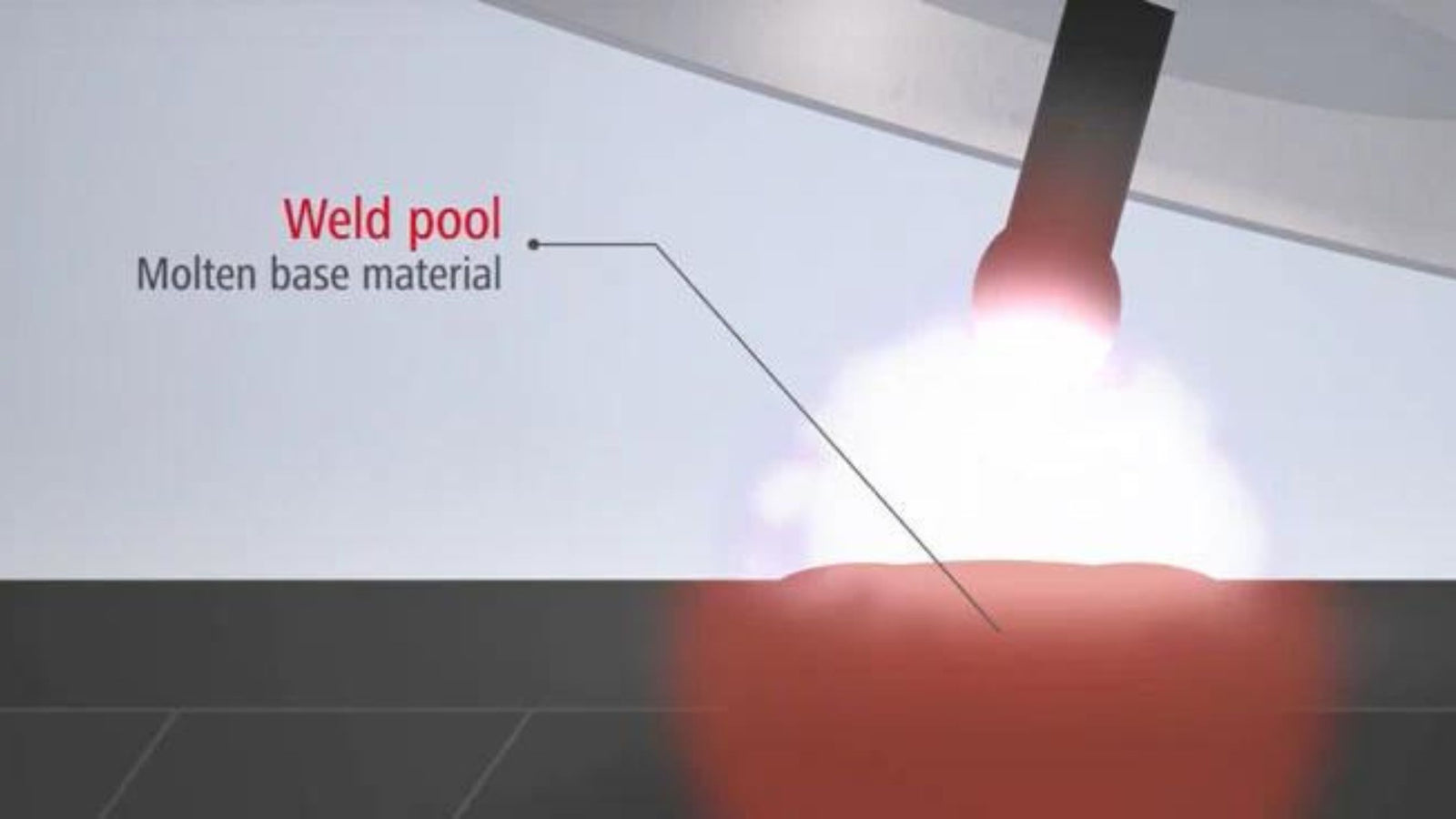

Short arc or dip transfer welding is a method where a short circuit is created between the electrode and the workpiece. In this technique, the electrode is continuously in contact with the workpiece, causing small droplets of molten metal to detach from the electrode and transfer to the workpiece. The arc is then reignited, and the process repeats.

This welding method is characterised by its low heat input and relatively low deposition rates. It is commonly used for welding thin materials, as it helps minimize the risk of burn-through and distortion. Short arc or dip transfer welding produces a stable and controlled arc, making it suitable for welding in all positions.

How Does Dip Transfer Welding Work?

MIG MAG welding is an arc process whereby you have a positive ( welding torch ) and a negative ( earth clamp) connected to a transformer or inverter power supply.

The earth clamp is placed on the material to be joined and the torch provides the filler wire to generate the explosion (arc).

Voltage is important

The welding wire is essentially a fuse, the same as in a mains electrical box that is designed to “blow” at a certain current (amps). On the front of the welding machine is a voltage switch that enables you to select different voltage settings. The lower the voltage the lower the explosion of the wire, the higher the voltage the higher the explosion.

MIG Wire Blow Off

Depending on the wire diameter and the voltage selected determines how big your explosion will be when the wire “shorts” or “blows” on the workpiece. This explosion blows off a length of wire (say for argument 5mm) and that would be essentially it but on a MIG MAG welder, we have a continuous wire and a motor that replaces the blown off length of wire to short again.

In the UK we have 50hz mains supply and in the USA 60Hz, this means that it is possible to have 50 or 60 explosions per second.

Achieve Resonant Frequency

So when you select a voltage you get a length of wire blown off (5mm), you then need to turn your wire speed up so that 5mm is sticking out of your welding contact tip for the next explosion. You then keep turning your speed up till you get that nice crackly bacon sound, we call this resonant frequency, which basically means you are matching the amount of wire sticking out of your tip with the frequency of explosions per second.

50x5mm per second

Applications of Short Arc or Dip Transfer Welding

Short arc or dip transfer welding finds its application in various scenarios, including:

- Joining thin sheet metal components, such as automotive body panels.

- Repairing delicate or heat-sensitive materials.

- Welding in all positions, including overhead and vertical positions.

- Performing root pass welding in pipe fabrication.

FAQs

Q1: What is dip transfer used for?

Dip transfer, also known as short arc transfer, is commonly used for welding thin materials. It is particularly suitable for applications where minimizing heat input and reducing the risk of burn-through and distortion are important. Dip transfer welding is often employed for joining delicate or heat-sensitive materials, performing root pass welding in pipe fabrication, and welding thin sheet metal components like automotive body panels.

Q2: What is dip vs spray transfer?

Dip transfer and spray transfer are two different modes of metal transfer in welding.

In dip transfer, the electrode remains in constant contact with the weld pool, creating small droplets of molten metal that detach and transfer to the workpiece. This mode of transfer is produces a lower heat input, controlled arc, and suitability for welding in all positions compared to spray or globular transfer. Dip transfer is commonly used for thin materials and applications that require precise control over the welding process.

In spray transfer, the electrode operates at a higher current level, resulting in a spray of tiny molten droplets that transfer to the workpiece. Spray transfer provides higher deposition rates and deeper penetration compared to dip transfer. It is typically used for welding thicker materials that require greater heat input and for achieving higher productivity in certain applications.

Q3: What are the three types of weld transfer?

The three types of weld transfer commonly recognised in welding are:

-

Dip Transfer (Short Arc Transfer): This transfer mode involves the formation of small droplets of molten metal that detach from the electrode and transfer to the workpiece. It is characterised by low heat input and controlled arc, making it suitable for thin materials and all-position welding.

-

Spray Transfer: In spray transfer, the welding current is higher, resulting in a spray of small molten droplets that transfer to the workpiece. Spray transfer provides higher deposition rates and deeper penetration, making it suitable for welding thicker materials and achieving higher productivity.

-

Globular Transfer: Globular transfer involves the formation of larger molten metal droplets that transfer to the workpiece. This transfer mode is typically used with higher current levels and is less common than dip transfer and spray transfer. It is often employed for welding certain types of flux-cored arc welding (FCAW) applications.

Q4: What are transfer modes for welding?

In welding, the term "transfer modes" refers to the different ways in which the molten metal is transferred from the electrode to the workpiece during the welding process. The most common transfer modes in welding include dip transfer, spray transfer, and globular transfer. These transfer modes are characterised by variations in heat input, arc stability, deposition rates, and suitability for different materials and applications. Selecting the appropriate transfer mode is essential to achieve desired weld quality, control, and productivity based on the specific requirements of the welding project.

Which gases are used in MIG MAG welding and what does it do?

|

Paul Jones Director BWS Ltd, CSWIP Ive been a welding engineer for over 30 years and a welding inspector for 23 years with vast experience of welding and related topics. |

References

https://www.fronius.com/en-us/usa/welding-technology/world-of-welding/mig-mag-welding

Updated 15/7/2023

Leave a comment

Comments will be approved before showing up.