Your Cart is Empty

Need Some Help? 0161 223 1843

Need Some Help? 0161 223 1843

BODYSHOP

WORKSHOP

WELDING

TOOLS

Telwin Technomig 243 Wave Review

February 21, 2020 4 min read

Is The Future of Bodyshop Welding Equipment Here?

The NEW Telwin Technomig 243 Wave is the latest multipurpose welder to come out aimed at the modern bodyshop and workshop.

It's a 230v compact Inverter Pulsed MIG MAG MMA welder with three MIG welding torches so that you are always ready to weld no matter what material.

The 243 Wave is perfect for a modern vehicle body repair shop as you can set the machine up to weld mild steel on one torch, MIG Braze and Aluminium on the other two. It also has the facility to fit a spool on welding torch for added options.

Control

It has 25 synergic programmes preset into the control for ease of use.

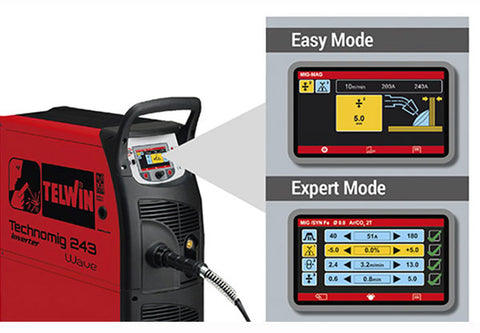

The simple to use digital display is easy to navigate and enables quick selection of the desired welding process.

I really liked the main display as it showed the desired material thickness to be welded and a really easy to understand graphic of a MIG torch welding a T fillet.

As you increased the thickness setting using the centre knob on the display, the T fillet showed itself getting thicker. Altering the trim setting enables the operator to move away from the synergic setting by plus or minus 5%. This again shows on the display. One thing most people don't understand about synergic displays is what the trim does, how to use it and what it adjusts. Read my blog post on "What synergic. I found it a little frustrating that the knob for the control is a little small and with welding gauntlets on it can be a little sensitive to set. Unfortunately, this seems to be the norm with all modern inverter sets for there synergic function. I did get used to it and once your functions had been set it was quick to adjust.

Design

The Telwin Wave 243 case style is tall and slim as it is in most of there new range. There is space on the rear to fit two midi gas bottles perfect for one Argon 5% and one pure Argon for aluminium and braze. There are three-compartment doors for each welding process, all able to fit 5kg spools. Unfortunately, due to the thinness of the design, there is no option to fit a15Kg spool something though that I feel you won't miss. Two of the compartments have single drive roller setups and one has 4 rolls, for aluminium. The wheels on the front are a little small and made of solid plastic so I think they may be troublesome on bad floors but other than that on a modern bodyshop/workshop floor the machine is easy to manoeuvre.

Welding Processes

Telwin Wave 243 has lots of different functions including MIG MAG TIG and MMA.

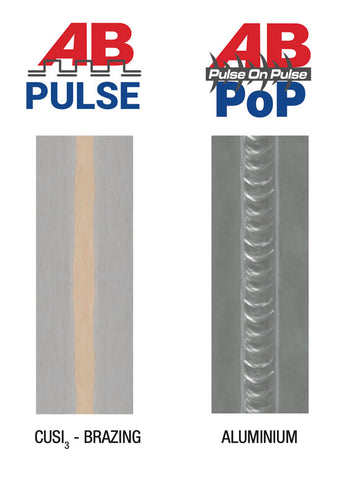

MIG MAG includes Dip transfer, Pulsed and Pulse on Pulse welding or "POP" as Telwin call it. It also has a special function for root welding that enables you to put in a butt root weld more easily in fabrication.

It also has ATC (Advanced Thermal Control) which is a special setting to give low thermal transfer when welding thin materials. This though can be a little confusing for the welder/technician as it makes the weld sound not quite right! I have heard many people say it doesn't sing or sound like crackly bacon when welding and they are right, the ATC function does give a colder more crackly arc than most people are using too compared with normal transformer MIG welders. It works well though and once you get used to the different sound it does in fact keep the heat down when welding thinner materials.

Advantages:

• easy welding of thin materials

• decreased deformation of the material

• extremely stable arc even when working with low currents

• rapid and accurate tack welding

• easier coupling of spaced sheets

• excellent results on steel, aluminium and during brazing operations

Torch Selection

To select a new process is quite easy as all you do is pick up the desired torch and press the trigger for a few seconds. The control will automatically switch to that torches synergic setting. This is great for switching between processes and materials.

The Pulsed feature on this machine is quite smooth and essential when welding MIG Braze slots and aluminium.

The increased use of aluminium panels on vehicles is making the use of pulsed welding machines in the bodyshop essential. Don't believe what sales representatives tell you, you cant weld aluminium body panels using the dip transfer process. Take a look at my posts on what is dip transfer welding and what is pulsed welding. The POP feature is perfect for welding aluminium enabling the welder/ technician to get the pretty penny stacking appearance of the weld bead.

Conclusion

In my opinion, the Telwin Technomig 243 Wave is a perfect welder for a modern bodyshop. The ATC function enables smooth welding of butt welds on quarter panels in steel and the pulsed function is excellent for Aluminium and MIG Braze.

The 3 torches enable the setup of all the different materials Steel, MIG Braze and Aluminium so this saves you time. The synergic settings are easy to use and the display is clear. The most important part though is that it welds well on all processes.

The things I don't like are the wheels are a little plasticky and could cause problems on rough floors, and the double pulse function can be a little tricky to set up.

FRONT PANEL INSTRUCTIONS

|

Paul Jones Director BWS Ltd, CSWIP Ive been a welding engineer for over 30 years and a welding inspector for 23 years with vast experience of welding and related topics. |

Leave a comment

Comments will be approved before showing up.